Purio Project

The circular economy stops being a theory and becomes a tangible reality with Lidl Spain’s Purio project. On October 9, 2025, Lidl Spain presented an innovative circular economy project: transforming the transparent plastic film from its pallets into six types of Purio trash bags. These bags, with capacities ranging from 10 to 100 liters and containing between 20% and 50% recycled material, are already available in more than 700 stores. The result is useful products for consumers that originate from internal waste and are certified by AENOR for circular economy, guaranteeing traceability and authenticity of the recycled content.

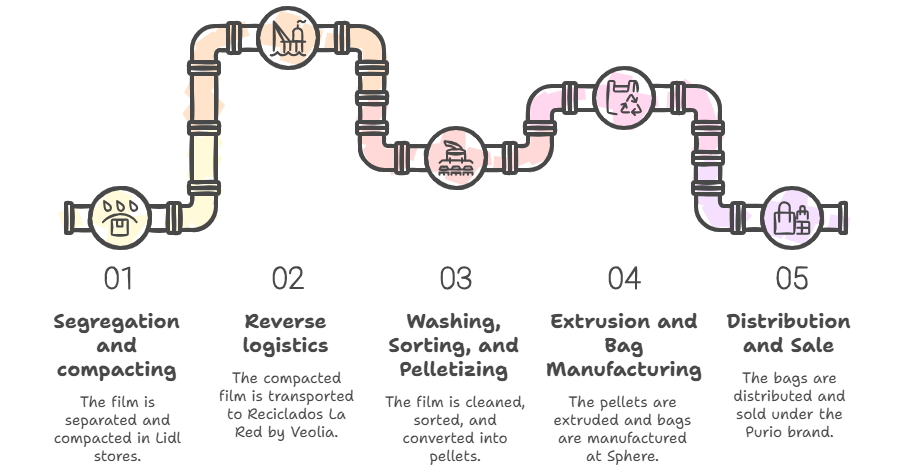

The project is built on a well-defined and entirely national value chain. Lidl separates and compacts the film in its stores and logistics platforms, ensuring the material arrives clean and homogeneous. At Reciclados La Red by Veolia, we receive this material and subject it to washing, sorting, and pelletizing, transforming it into high-quality recycled granules. Sphere España, from its plant in Pedrola (Zaragoza), uses these granules to manufacture Purio bags through extrusion and blowing processes, before distributing them to Lidl stores again.

This project is the first in Spain to obtain AENOR’s circular economy certification for a private label product. The certification guarantees traceability from the waste to the final product and verifies the recycled content.

Impact and key figures

- More than 1,500 tons of recycled plastic.

- Forecast of 16 million bags sold by the end of 2026.

- Six varieties with capacities ranging from 10 to 100 liters.

- Recycled content between 20% and 50%.

Operational process

This “own waste” model closes the loop within the country and facilitates complete traceability of the flow, from the origin of the waste to the final product on the shelf. Additionally, it demonstrates that collaboration between companies with complementary roles can generate sustainable and scalable solutions. Lidl provides the waste and reverse logistics, Reciclados La Red by Veolia guarantees industrial transformation with quality and traceability, and Sphere España turns the recycled raw material into a final product that meets the necessary mechanical and durability requirements.

Although the recycled content is not total due to technical requirements, the project represents a significant step forward in reducing the use of virgin plastic and in adding value to internal waste. It is a clear example of how the circular economy can be integrated into the daily operations of large companies, generating environmental benefits and offering consumers responsible products.