by webmasterMT | Oct 15, 2025 | Innovation, recycled material, Recycling, Sustainability

Purio Project

The circular economy stops being a theory and becomes a tangible reality with Lidl Spain’s Purio project. On October 9, 2025, Lidl Spain presented an innovative circular economy project: transforming the transparent plastic film from its pallets into six types of Purio trash bags. These bags, with capacities ranging from 10 to 100 liters and containing between 20% and 50% recycled material, are already available in more than 700 stores. The result is useful products for consumers that originate from internal waste and are certified by AENOR for circular economy, guaranteeing traceability and authenticity of the recycled content.

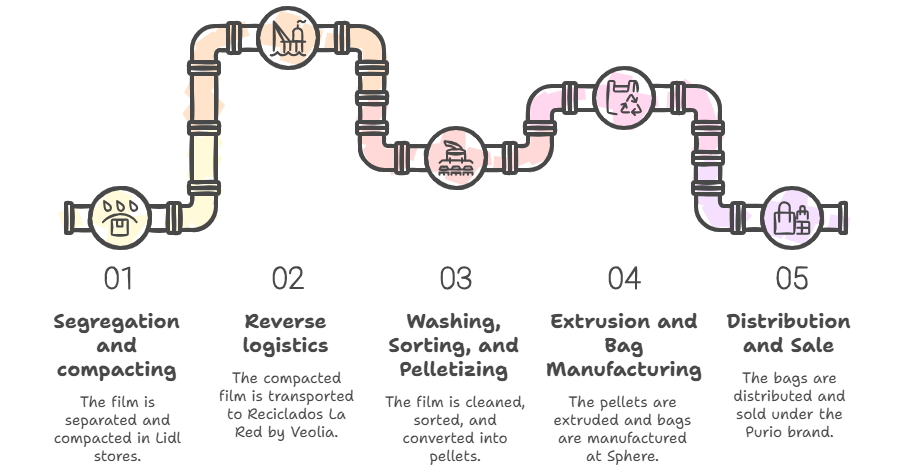

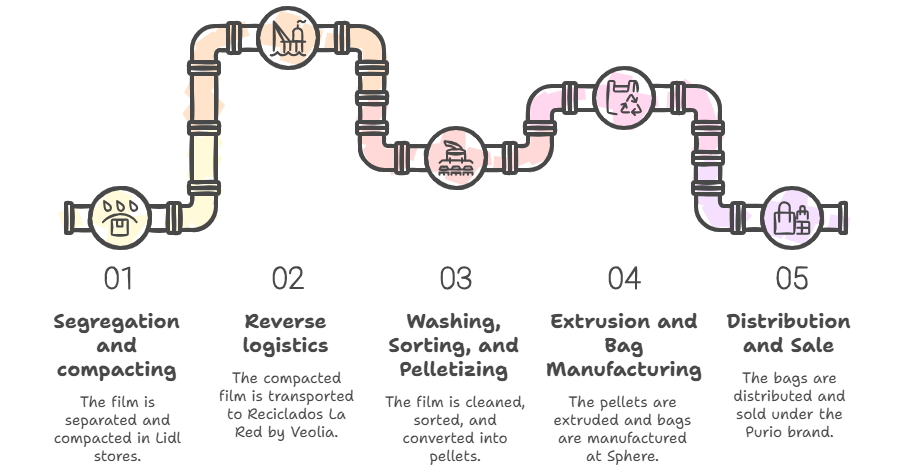

The project is built on a well-defined and entirely national value chain. Lidl separates and compacts the film in its stores and logistics platforms, ensuring the material arrives clean and homogeneous. At Reciclados La Red by Veolia, we receive this material and subject it to washing, sorting, and pelletizing, transforming it into high-quality recycled granules. Sphere España, from its plant in Pedrola (Zaragoza), uses these granules to manufacture Purio bags through extrusion and blowing processes, before distributing them to Lidl stores again.

This project is the first in Spain to obtain AENOR’s circular economy certification for a private label product. The certification guarantees traceability from the waste to the final product and verifies the recycled content.

Impact and key figures

- More than 1,500 tons of recycled plastic.

- Forecast of 16 million bags sold by the end of 2026.

- Six varieties with capacities ranging from 10 to 100 liters.

- Recycled content between 20% and 50%.

Operational process

This “own waste” model closes the loop within the country and facilitates complete traceability of the flow, from the origin of the waste to the final product on the shelf. Additionally, it demonstrates that collaboration between companies with complementary roles can generate sustainable and scalable solutions. Lidl provides the waste and reverse logistics, Reciclados La Red by Veolia guarantees industrial transformation with quality and traceability, and Sphere España turns the recycled raw material into a final product that meets the necessary mechanical and durability requirements.

Although the recycled content is not total due to technical requirements, the project represents a significant step forward in reducing the use of virgin plastic and in adding value to internal waste. It is a clear example of how the circular economy can be integrated into the daily operations of large companies, generating environmental benefits and offering consumers responsible products.

by webmasterMT | Oct 8, 2025 | Innovation, Recycling, Sustainability

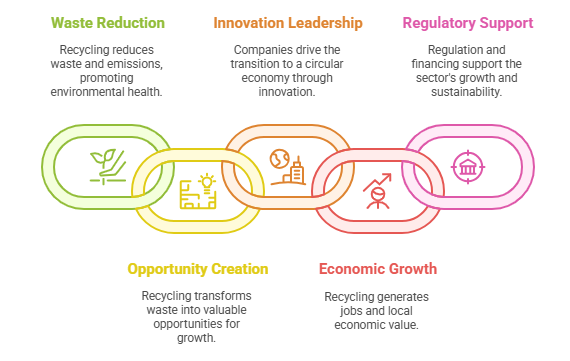

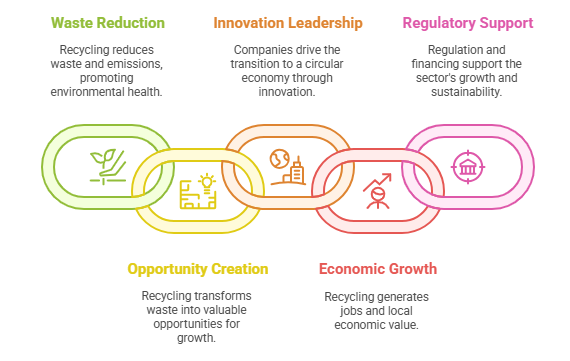

The circular economy is much more than a trend: it is an urgent necessity to ensure a sustainable future. In Spain, recycled plastic has become a key pillar to closing the material life cycle, reducing environmental impact, and generating new economic opportunities.

At Reciclados La Red by Veolia, we work every day to transform plastic waste into high-quality raw material, ready to be used in responsible manufacturing processes.

The role of recycled plastic in the circular economy

Recycled plastic is key to closing the production cycle. By reincorporating this material into manufacturing:

- Fossil resource extraction is reduced.

- The carbon footprint decreases.

- Tons of plastic are prevented from ending up in landfills or oceans.

Environmental benefits

- Lower energy consumption compared to virgin plastic production.

- Reduction of CO₂ emissions.

- Conservation of ecosystems.

Economic benefits

- Savings in production costs.

- Creation of green jobs.

- Boost to innovation in materials.

The situation of recycled plastic in Spain

Spain has made notable progress in plastic recycling, but there is still a way to go. According to data from PlasticsEurope, the country recycles more than 40% of its plastic waste, and the trend is growing.

At Reciclados La Red by Veolia, we contribute to this progress with advanced technology and certified processes that guarantee the quality of recycled plastic.

Success stories and applications of recycled plastic

Recycled plastic is used in:

- Packaging and containers.

- Automotive components.

- Urban furniture.

- Construction products.

Practical example

An urban furniture company that uses recycled polyethylene reduces its carbon footprint and improves its brand image.

How your company can benefit

If your business uses plastic, incorporating recycled material can:

- Comply with environmental regulations.

- Improve corporate reputation.

- Reduce costs.

On our recycled products page you will find options tailored to your needs.

Challenges and opportunities

Although plastic recycling presents challenges such as selective collection and material quality, the opportunities are enormous:

- Process innovation.

- New markets.

- Strategic collaborations.

Contribute to the circular economy

Every action counts. From properly separating waste to choosing responsible suppliers, we can all drive the circular economy.

Recycled plastic is a powerful tool to advance towards a circular economy in Spain. At Reciclados La Red by Veolia, we are committed to sustainability and innovation.

Do you want to incorporate recycled plastic into your processes? Contact us today and take the next step towards a more sustainable future.

by webmasterMT | Sep 9, 2025 | Innovation, Legislation, Recycling, Sustainability

The future of plastic recycling in Spain after EU Regulation 2025/40

The plastic recycling sector is undergoing a true revolution. The new Regulation (EU) 2025/40 on packaging and packaging waste, approved by the European Union, marks a turning point for companies like Reciclados La Red by Veolia. This regulation replaces the 1994 Directive and establishes a stricter and more harmonized legal framework, forcing Spain to adapt its national legislation.

What is EU Regulation 2025/40 on packaging and waste?

Regulation EU 2025/40 is a direct response to the need to reduce packaging waste and promote the circular economy. Its goal is clear: minimize the environmental impact of packaging, increase reuse and recycling, and ensure that all EU countries follow the same rules.

Main new features of the Regulation

- Strict limits on the use of single-use packaging.

- More ambitious recycling targets.

- Requirements for minimum recycled content in packaging.

- Rules to improve recyclability and reuse of packaging.

- Greater transparency and traceability in the recycling chain.

Sustainability and circular economy goals

The Regulation drives the transition towards a circular economy, where waste becomes resources. For companies like Reciclados La Red by Veolia, this means new opportunities and responsibilities.

How does Regulation EU 2025/40 affect plastic recycling companies?

Challenges for recycling companies

Adapting to the new quality standards is one of the main challenges. The Regulation requires recycled plastic to meet stricter technical and safety requirements. In addition, controls and documentation are increased to guarantee the traceability of recycled material.

Companies will need to invest in technology and training to comply with these standards. It will also be necessary to improve separation and sorting processes to ensure the purity of recycled plastic.

Benefits and opportunities for the sector

The Regulation creates a larger and more uniform market for recycled plastic. By requiring packaging to contain a minimum percentage of recycled material, it increases demand for this product. This represents a unique opportunity for companies like Reciclados La Red by Veolia.

Moreover, the harmonization of standards facilitates the export of recycled plastic to other EU countries, removing legal barriers and opening up new business possibilities.

Key Challenges for Reciclados La Red by Veolia

Adapting to New Quality Standards

The quality of recycled plastic will be a key factor for competing in the new European market. Reciclados La Red by Veolia is investing in cutting-edge technology to ensure its product meets the most demanding requirements.

Traceability and Transparency in the Recycling Process

The Regulation requires full traceability of recycled material. This involves recording and documenting every stage of the process, from collection to the sale of the final product. Transparency will be fundamental to gain customers’ trust and comply with regulations.

Benefits of the New Regulation for Reciclados La Red by Veolia

Increase in Demand for Recycled Plastic

The obligation to include a minimum percentage of recycled plastic in packaging multiplies business opportunities. Reciclados La Red by Veolia is prepared to meet this growing demand by offering high-quality and sustainable products.

Expansion into the European Market

The harmonization of standards facilitates entry into new markets within the EU. This allows Reciclados La Red by Veolia to expand its customer network and consolidate its position as a benchmark in the sector.

How to Prepare for the Future of Plastic Recycling

Innovation and Collaboration in the Value Chain

Innovation will be key to adapting to new challenges. Reciclados La Red by Veolia is committed to collaborating with clients, suppliers, and other companies in the sector to develop innovative and sustainable solutions.

Training and Awareness

Continuous training of the team and raising awareness among clients are essential to comply with regulations and take advantage of the opportunities offered by EU Regulation 2025/40.

Conclusion and Call to Action

The new EU Regulation 2025/40 represents a challenge, but also a great opportunity for plastic recycling companies. At Reciclados La Red by Veolia, we are committed to sustainability and prepared to lead the transition towards a circular economy. Would you like to know how we can help you comply with the new regulations? Contact us and discover our recycled plastic solutions!

by webmasterMT | Jul 16, 2025 | Circular Economy, Innovation, recycled material, Recycling, Sustainability

Discover how plastic recycling drives the circular economy and protects the environment

The challenge of turning waste into resources: current challenges

In recent years, the perception of plastic has changed radically. Many see it as the great environmental villain, but the reality is more complex. The real problem is not the material itself, but how we manage it after use. The accumulation of plastic waste in landfills and oceans, microplastic pollution, and dependence on fossil resources are just some of the consequences of a linear system of production and consumption.

Inadequate management of plastic waste generates profound environmental and social impacts. For example, the lack of selective collection infrastructure in many regions makes effective recycling difficult. This causes tons of plastics to end up in landfills or, worse, in natural environments, affecting biodiversity and human health.

Moreover, misinformation about recycling contributes to low citizen participation. Many people don’t know which types of plastics can be recycled or how they should be disposed of. This confusion reduces the quality of the recovered material and increases industrial processing costs.

On the other hand, the industry faces the challenge of ensuring the traceability and quality of recycled plastic. Customers demand safe, certified materials with technical properties equivalent to virgin plastics. Meeting these standards requires technological innovation and rigorous controls. At Reciclados La Red by Veolia, we work day by day to meet these quality and traceability standards, for example, by obtaining the UNE-EN 15343 Post-Consumer Recycled Plastic Traceability Certificate.

A clear example is the food sector, where regulations require recycled packaging to meet strict safety requirements. This forces recycling companies to invest in advanced decontamination and traceability technologies.

Ultimately, the challenge is twofold: to educate society about the importance of recycling and to equip the industry with tools to turn waste into high-quality raw materials. Only then will we be able to stop seeing plastic as an enemy and make it an ally of the circular economy.

Innovation and technology: plastic recycling as a driver of change

The circular economy proposes a model where materials are kept in use for as long as possible. In this context, plastic recycling is a key piece. Thanks to innovation, it is now possible to transform plastic waste into new high value-added products, reducing the carbon footprint and dependence on fossil resources.

Mechanical recycling: efficiency and quality

Mechanical recycling is the most widespread process for recovering post-consumer plastics. It consists of collecting, sorting, shredding, washing, and extruding the material. This technology makes it possible to obtain recycled pellets suitable for manufacturing packaging, industrial components, and textiles. For example, at Reciclados La Red by Veolia, we use optical sorting systems and hot washing to guarantee the purity of recycled plastic, achieving a 70% reduction in CO₂ emissions compared to virgin plastic.

Chemical recycling: closing the loop

When plastic waste is difficult to recycle mechanically, chemical recycling offers an innovative alternative. Through processes like pyrolysis or depolymerization, plastics are turned into monomers or oils that can be reused in the petrochemical industry. This allows complex materials to be recycled and expands the range of applications for recycled plastic. The integration of both technologies is fundamental to achieving recycling rates above 50% in the coming years.

Circular economy and traceability

Traceability is essential to guarantee the quality and safety of recycled plastic. Thanks to digital systems and certifications, it is possible to track the material from its collection to its final transformation. This provides confidence to customers and facilitates compliance with increasingly demanding European regulations. In addition, the circular economy generates local jobs and encourages innovation throughout the value chain.

Education and awareness

Citizen awareness is the first step towards effective recycling. Educational campaigns, school workshops, and collaborations with municipalities are key tools to increase the selective collection rate. The greater the social participation, the greater the quantity and quality of recycled plastic available to industry.

Tangible results: success stories in plastic recycling

Case 1: Sustainable innovation in post-consumer black LDPE

At Reciclados La Red by Veolia we have implemented major improvements in the production process of post-consumer commercial black LDPE, committed to sustainable innovation. Thanks to a series of technical advances, we have significantly raised the quality and sustainability standards of our product. The main improvements include reducing the temperature during recycling, incorporating advanced filtration systems to achieve greater purity, and precise homogenization that guarantees uniformity and quality control in each batch. These innovations allow us to offer recycled LDPE that not only meets, but exceeds, market expectations in terms of performance, durability, and environmental commitment.

Case 2: Recycled PET for food packaging

TorrePET by Veolia processes 60,000 tons of plastic waste per year. Thanks to decontamination technology, high-quality food-grade recycled PET pellets are produced. Recycled PET makes it possible to reduce the carbon footprint of packaging without compromising safety.

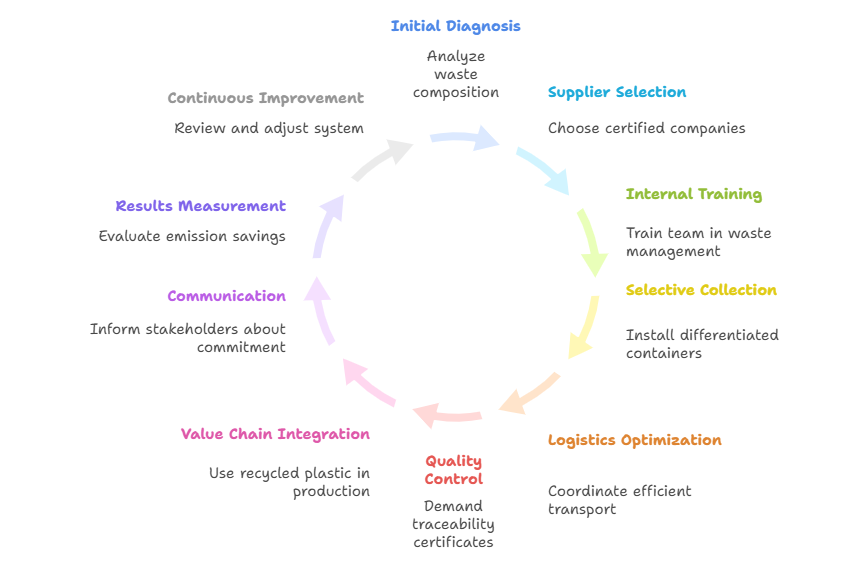

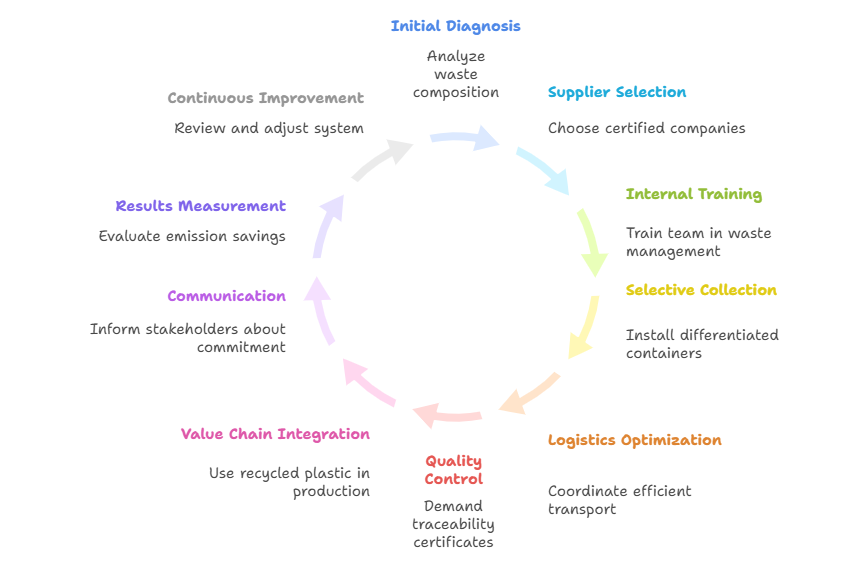

How to implement plastic recycling in your company: roadmap

The time to act: together for a circular future

Plastic recycling is much more than a trend: it is an urgent necessity to protect the planet and ensure business competitiveness. Every recycled package, every kilo of recovered plastic, adds up to building a real circular economy. At Reciclados La Red by Veolia, we believe in the power of collaboration and innovation to turn waste into opportunities.

We invite you to join this movement. Whether you are a customer, supplier, or citizen, your role is key. Get informed, participate, and demand products made with recycled plastic. Together, we can show that plastic is not the enemy, but a valuable resource when managed responsibly.

Contact our team to start your circular transition.

by webmasterMT | May 27, 2025 | Circular Economy, Environment, Innovation, recycled material, Recycling, Sustainability

Innovation and Transparency in the LDPE Recycling Industry

At Reciclados La Red by Veolia, innovation and transparency go hand in hand. We recently held an Open Day focused on LDPE quality improvements, giving clients and partners the opportunity to gain detailed insight into our advancements in plastic recycling.

Looking for examples of industrial sustainability? This event highlighted the potential of new technologies applied to LDPE recycling.

Why Hold an Open Day in LDPE Recycling?

Efficient plastic recycling is a global priority. Organizing these open days allows our clients to see, first-hand, how investments and technical upgrades transform production processes.

Importance for Clients and the Industrial Sector

Trust is built through transparency. We invited our clients to discover step-by-step how we manage LDPE and how our recent investments have improved product quality.

Boosting the Circular Economy in Spain

These initiatives reinforce our commitment to the circular economy and to sustainability in Spain’s plastic recycling industry.

LDPE Quality Improvements: The Key to Advanced Recycling

During our presentation, we detailed the advances incorporated into our LDPE recycling processes.

New Post-Industrial LDPE Sorting Plant

- Precise separation of contaminants and colored film.

- Dramatic reduction in black spots.

- Greater cleanliness and product uniformity.

Homogenizer Silo and Parameter Controls

- Total homogenization of color, flow, and density.

- Odor reduction.

- Transition from manual to automatic operation by June 2025.

Innovative Washing Water Separation System

- Dual-circuit: clean and waste water.

- Improved filtering efficiency and reduced environmental footprint.

- New dedicated water treatment plant operational by the end of May.

Tour of Our Facilities: Total Transparency in LDPE Recycling

Participants enjoyed an immersive experience at our La Red Hacienda Dolores, La Red Central, and Ecores plants.

La Red Hacienda Dolores: Innovation in Action

Here, we offered a practical demonstration of technical advances in LDPE sorting and processing.

La Red Central and Ecores: Process Optimization

Here, we showcased improvements in operational efficiency and technological integration to deliver consistently high-quality recycled products.

Results of Quality Improvements in LDPE Recycling

The benefits of these investments are already being seen by our clients.

Benefits for Clients: Homogeneous and Reliable Products

- Fewer incidents and defects.

- Consistent quality from batch to batch.

- Reduction in contamination and cross-batch issues.

Reduced Defects and Greater Traceability

- Implementation of advanced traceability systems.

- Use of technology aligned with European standards.

Our Commitment: A Sustainable Future and Ongoing Improvements

We are already working on new projects to further enhance the efficiency, sustainability, and quality of LDPE recycling. Our 2025 vision includes digitalization of controls, reduced energy consumption, and new sorting lines.

Photo Gallery: The Day in Images

Conclusion: Transparency in Plastic Recycling Drives Trust

Showcasing our improvements and opening our doors to clients strengthens trust, generates new opportunities, and helps build a robust circular economy in Spain.

To learn more, contact us or visit our product and sustainability pages.

by webmasterMT | May 19, 2025 | Circular Economy, Environment, Innovation, recycled material, Recycling, Sustainability

May 17 is a marked date on the environmental calendar: World Recycling Day. This day seeks to reflect on our consumption habits and waste management, especially plastic, one of the most prevalent and controversial materials of our time.

From Recycled La Red by Veolia, we want to show you why plastic recycling is essential to achieve an efficient and responsible circular economy. Why do we celebrate World Recycling Day?

Origin and objectives of World Recycling Day

This event, promoted by UNESCO, seeks to raise awareness of the importance of reusing and recycling materials to reduce pressure on natural resources.

Global importance of plastic recycling

Recycling directly contributes to waste and CO2 emission reduction. Recycled plastic prevents tons of waste from ending up in landfills and oceans every year.

The impact of plastic recycling on the circular economy

Environmental advantages of recycled plastic

The use of recycled plastic in products and packaging reduces oil extraction, saves energy and significantly decreases the carbon footprint.

Resource saving and waste reduction

Each team and machine at Recycled La Red by Veolia aims to transform waste into raw material, which promotes circularity and protects ecosystems.

Data from PlasticEurope shows that in Europe, more and more companies are taking advantage of recycled plastic, surpassing 5 million tons reused annually (source: https://plasticseurope.org).

Recycled La Red by Veolia: Our work in plastic recycling

Recycling process at our plant in Spain

At our facilities, we collect, classify and treat plastic waste according to the strictest European standards. We convert post-consumer and post-industrial waste into high-quality recycled plastic, ready to be transformed into new products.

Benefits of recycled plastic for businesses and consumers

Recycled plastic is a valid and sustainable alternative, ideal for sectors such as packaging, automotive or construction. It provides clear economic and environmental benefits.

How you can contribute to plastic recycling

Practical tips to improve recycling at home and in the office

- Separate the types of plastics correctly in the yellow containers.

- Reduce the consumption of single-use plastics.

- Find out about the clean points in your city.

- The importance of separation and selective collection

- Correct separation facilitates recycling, increasing the quality of the recovered materials and avoiding rejections. Learn to read labels well and follow local informative campaigns.

The future of recycled plastic in Spain and the world

Innovations and trends in plastic recycling

The implementation of new technologies or the new advanced recycled resins progress in efficiency and purity, opening new applications for recycled plastic.

Institutional support and new European regulations

The European Union promotes regulatory frameworks such as the European Plastic Strategy, demanding higher recycling rates and the design of more sustainable packaging (source: https://europa.eu).

In Spain, the National Integrated Waste Plan strengthens the recycling chain from collection to the eco-design of new products.

Do you want to boost plastic recycling? Visit our website and find out how we can help you take the next step towards sustainability.

Plastic recycling is a real opportunity to transform waste into resources. Our environmental commitment is realized day by day, driving the change towards a cleaner and more prosperous planet for everyone.